HACCP – LEVEL 3 Training Course

This Level 3 HACCP training course is designed to help learners understand more about what’s involved in a successful HACCP food safety management system. The course outlines each essential step of the HACCP planning process and aids you to understand how to identify food safety hazards, select relevant control measures and ensure the HACCP system continues to operate efficiently and effectively. (online class available)

Entry Requirements

“HACCP Level 3 Participants should hold relavent food safety qualification and possess a good working knowledge of their industry sector.” Related Course HACCP, ISO 22000

Learn HACCP Principles

- Conduct a hazard analysis:Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A food safety hazard is any biological, chemical, or physical property that may cause a food to be unsafe for human consumption.

- Identify critical control points: A critical control point (CCP) is a point, step, or procedure in a food manufacturing process at which control can be applied and, as a result, a food safety hazard can be prevented, eliminated, or reduced to an acceptable level.

- Establish critical limits for each critical control point: A critical limit is the maximum or minimum value to which a physical, biological, or chemical hazard must be controlled at a critical control point to prevent, eliminate, or reduce that hazard to an acceptable level.

- Establish critical control point monitoring requirements: Monitoring activities are necessary to ensure that the process is under control at each critical control point. In the United States, the FSIS requires that each monitoring procedure and its frequency be listed in the HACCP plan.

- Establish corrective actions: These are actions to be taken when monitoring indicates a deviation from an established critical limit. The final rule requires a plant’s HACCP plan to identify the corrective actions to be taken if a critical limit is not met. Corrective actions are intended to ensure that no product is injurious to health or otherwise adulterated as a result if the deviation enters commerce.

- Establish procedures for ensuring the HACCP system is working as intended: Validation ensures that the plants do what they were designed to do; that is, they are successful in ensuring the production of a safe product. Plants will be required to validate their own HACCP plans. FSIS will not approve HACCP plans in advance, but will review them for conformance with the final rule. Verification also includes ‘validation’ – the process of finding evidence for the accuracy of the HACCP system (e.g. scientific evidence for critical limitations).

- Establish record keeping procedures : The HACCP regulation requires that all plants maintain certain documents, including its hazard analysis and written HACCP plan, and records documenting the monitoring of critical control points, critical limits, verification activities, and the handling of processing deviations. Implementation involves monitoring, verifying, and validating of the daily work that is compliant with regulatory requirements in all stages all the time. The differences among those three types of work are given by Saskatchewan Agriculture and Food.

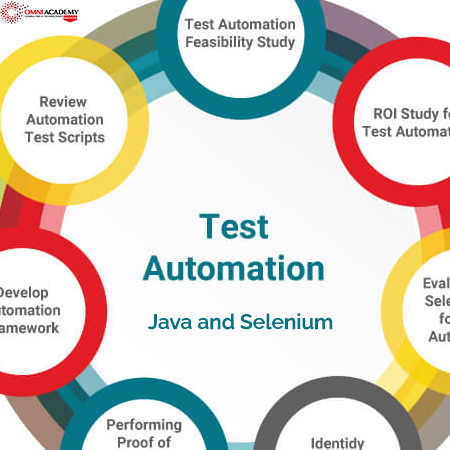

Learn HACCP Standards

The seven HACCP principles are included in the international standard ISO 22000 FSMS 2011. This standard is a complete food safety and quality management system incorporating the elements of prerequisite programmes HACCP and the quality management system, which together form an organization’s Total Quality Management system.

Other standards, such as Safe Quality Food Institute’s SQF Code, also relies upon the HACCP methodology as the basis for developing and maintaining food safety (level 2) and food quality (level 3) plans and programs in concert with the fundamental prerequisites of good manufacturing practices.

PECB Certified ISO 22001 Certificate (Sample)

HACCP Level 3 Course Key Learning

Section 1

- The Importance of Food Safety

- The Role and Benefits of HACCP

- Legal Obligations

- The Principles of HACCP

- The Practical Application of HACCP

- Designing the Plan (including group exercises)

- The Team Approach

- Hazard Analysis Methodology

- Identification of Critical Control Points

- Monitoring Procedures

- Implementation

- The Codex CCP Decision Tree

Section 2

- A short, work based assignment to be completed prior to the course.

Section 3

- Presentation by participants of work-based assignments and group discussion

- Verification and maintenance of HACCP systems

- Management of HACCP systems

Job Interview Preparation (Soft Skills Questions & Answers)

- Tough Open-Ended Job Interview Questions

- What to Wear for Best Job Interview Attire

- Job Interview Question- What are You Passionate About?

- How to Prepare for a Job Promotion Interview

Stay connected even when you’re apart

👬🏻Join our WhatsApp Channel – Get discount offers

🧮 500+ Free Certification Exam Practice Question and Answers

Internships, Freelance and Full-Time Work opportunities

👫🏻 Join Internships and Referral Program (click for details)

👫🏻 Work as Freelancer or Full-Time Employee (click for details)

Flexible Class Options

- Week End Classes For Professionals SAT | SUN

- Corporate Group Trainings Available

- Online Classes – Live Virtual Class (L.V.C), Online Training

Related Courses

ISO 9001:2015 – Lead Auditor Course

ISO 9001:2015 – Quality Management System

ISO 22000 – Food Safety Management

Hazard Analysis and Critical Control Point – HACCP

Safety Engineer Diploma Course